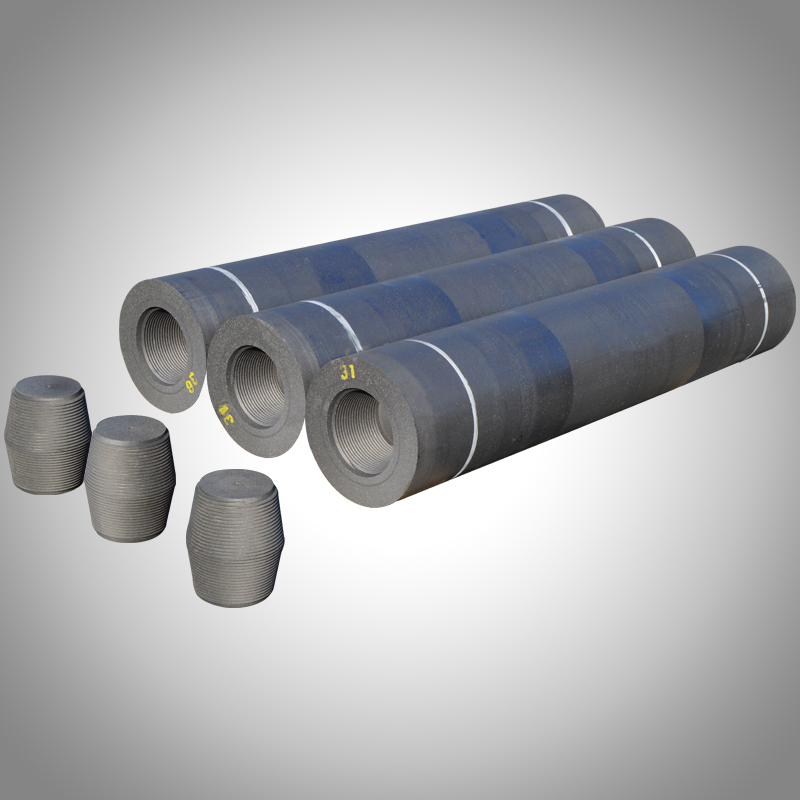

Graphite Electrode Guide

Graphite electrodes are used mainly in electric arc furnace steel production because they have the properties of high electrical conductivity.

Graphite electrodes are presently the only products available that have the high levels of electrical conductivity and the capability of sustaining the extremely high levels of heat generated in this demanding environment. They are used to refine steel in ladle furnaces and in other smelting processes. These act as conductors of electricity in the furnace, generating sufficient heat to melt scrap metal, iron ore or other raw materials used to produce steel or other metals. In a typical furnace using alternating current and operating at a typical number of production cycles per day, one of the nine electrodes is fully consumed (requiring the addition of a new electrode), on average, every eight to ten operating hours. The actual rate of consumption and addition of electrodes for a particular furnace depends primarily on the efficiency and productivity of the furnace.

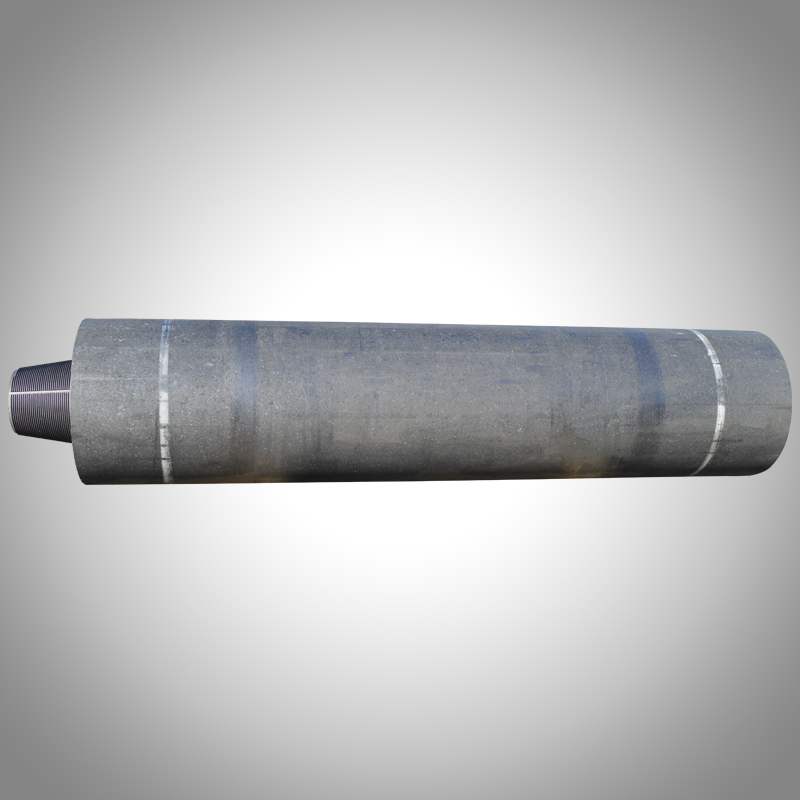

RP Graphite Electrode

RP GRAPHITE ELECTRODE – Good Electrical Conductivity, Low Consumption

RP graphite electrode is mainly used for regular power electric arc furnaces to smelt scrap steel, silicon and yellow phosphorus.

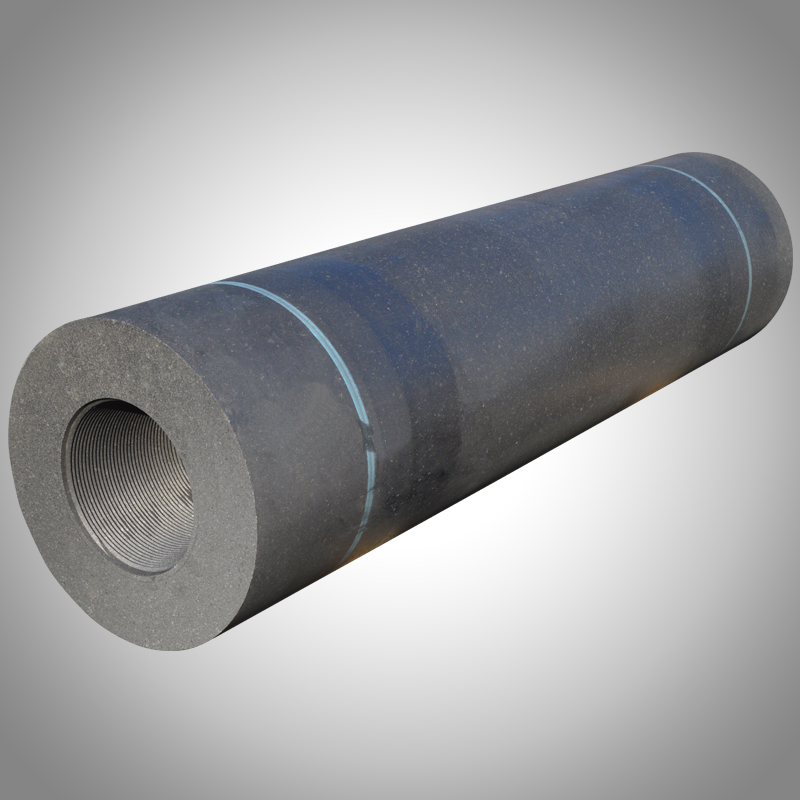

HP Graphite Electrode

HP GRAPHITE ELECTRODES – The Diameters Range From 200 Mm To 600 Mm

HP graphite electrode is mainly used for high power electric arc furnaces with the current density range of 18–25 A/cm2.

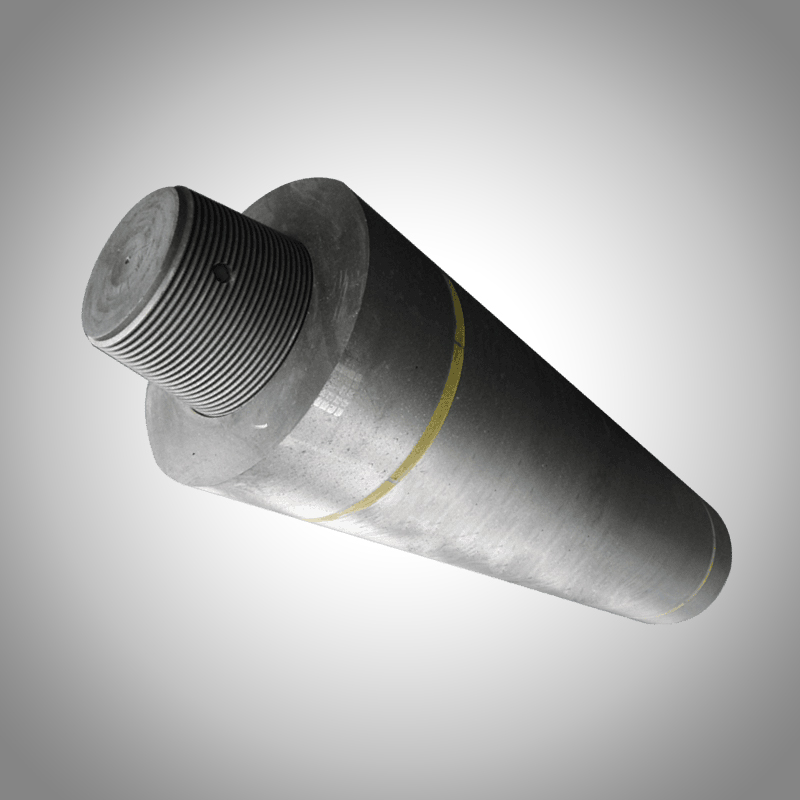

UHP Graphite Electrode

UHP GRAPHITE ELECTRODE – LOW ELECTRICAL RESISTANCE, HIGH DENSITY

UHP graphite electrode is mainly used for ultra high power electric arc furnaces with the current density greater than 25 A/cm2.